In the fast-evolving barefoot shoe industry, the quality and precision of sole molds are the backbone of creating high-performance, minimalist footwear that delivers the natural feel barefoot enthusiasts crave. As a leading Chinese barefoot shoe factory specializing in B2B cross-border trade, we partner with a world-class sole mold factory to provide global barefoot shoe brands with customized solutions that elevate their products. Our commitment to technical excellence, efficient execution, and uncompromising quality ensures that every barefoot shoe mold we produce meets the unique demands of minimalist footwear. Here’s why our sole mold factory stands out—and why it’s worth investing in quality for your barefoot shoe brand.

1. Precision Mold Design: Turning Barefoot Shoe Concepts into Reality

Accurate 3D Modeling and Simulation for Barefoot Shoe Soles

Our design team, composed of senior engineers with over a decade of experience, transforms your barefoot shoe concepts into precise 3D models using industry-leading software like UG and Pro/E. Unlike traditional mold factories, we go beyond basic geometry, factoring in critical injection molding parameters—such as pressure, temperature, and cooling time—to ensure flawless barefoot shoe soles from the start. Our proprietary mold condition simulation system allows us to conduct multidimensional analyses, including stress deformation and material flow, within just 72 hours. This proactive approach identifies potential issues like stress points or filling gaps, ensuring your barefoot shoe molds are optimized for production.

Standardized Design with a Wealth of Barefoot Shoe Expertise

With a database of over 2,000 successful barefoot shoe mold designs, covering everything from ultra-minimalist running shoes to casual barefoot sneakers, we bring unmatched expertise to every project. Whether it’s perfecting the heel curvature for natural foot alignment or crafting intricate anti-slip patterns for barefoot trail shoes, our designers leverage historical data and parameterized adjustments to meet your brand’s unique needs. Our streamlined process, managed by dedicated project managers, ensures that we deliver design drafts in as little as one working day, giving your barefoot shoe brand a competitive edge in fast-paced markets.

2. Uncompromising Material Selection: Built for Barefoot Shoe Durability

High-quality barefoot shoe molds start with premium materials. We carefully select mold steel based on your barefoot shoe production requirements, rigorously vetting supplier certifications and conducting in-house inspections. Our standardized storage systems prevent moisture and rust, while pre-processing treatments like annealing and forging enhance material performance. This meticulous approach ensures that every barefoot shoe mold we produce is durable, reliable, and ready to withstand the demands of high-volume minimalist shoe manufacturing.

3. Micron-Level Precision Manufacturing: Crafting Superior Barefoot Shoe Molds

Our state-of-the-art manufacturing facility uses advanced equipment like five-axis CNC machining centers and EDM tools to achieve micron-level precision in every barefoot shoe mold. With high-speed cutting and mirror-finish techniques, we ensure that each mold delivers consistent, high-quality soles for your minimalist footwear. Our intelligent production scheduling system enables 24/7 operations, allowing us to complete the entire mold-making process—from material preparation to assembly—in as little as 7 days for urgent orders, far surpassing the industry average of 15-20 days. Rigorous quality control, including self-inspections and random checks, guarantees that every barefoot shoe mold meets the highest standards.

4. Full Lifecycle Quality Assurance: Ensuring Long-Lasting Barefoot Shoe Molds

Comprehensive Mold Testing for Barefoot Shoe Production

Quality is at the heart of everything we do. Beyond standard dimensional checks, our sole mold factory conducts a unique “mold condition simulation test,” running each mold through 3,000 consecutive trial productions on injection molding machines. We monitor over 20 parameters, including mold opening/closing times, ejection resistance, and product shrinkage, to ensure stability in real-world barefoot shoe manufacturing. This rigorous testing minimizes defects and maximizes the yield rate, which consistently exceeds 99.2%.

Proactive Maintenance for Barefoot Shoe Mold Longevity

We treat every barefoot shoe mold as a long-term investment for your brand. Each mold comes with a dedicated file tracking usage, maintenance history, and service schedules. After every production run, our maintenance team cleans, lubricates, and rust-proofs the mold within 4 hours. For long-term partners, we offer free quarterly on-site maintenance, including precision calibration and preemptive replacement of wear-prone parts, ensuring your barefoot shoe molds remain in peak condition for years.

Why Choose Us for Your Barefoot Shoe Mold Needs?

In a market where many sole mold factories compete on price, we focus on delivering unmatched value through expertise, precision, and efficiency. Our partnership with a top-tier sole mold factory enables us to offer:

- Faster Delivery: Complete mold production in as little as 7 days.

- Enhanced Durability: 30% longer mold lifespan for cost-effective barefoot shoe production.

- Superior Quality: A yield rate of over 99.2%, minimizing defects in minimalist footwear.

Backed by years of serving over 300 renowned barefoot shoe brands, our team is committed to helping you create minimalist footwear that stands out in the global market. While our prices may be slightly above the market average, the exceptional quality, efficiency, and reliability of our barefoot shoe molds make every penny worthwhile.

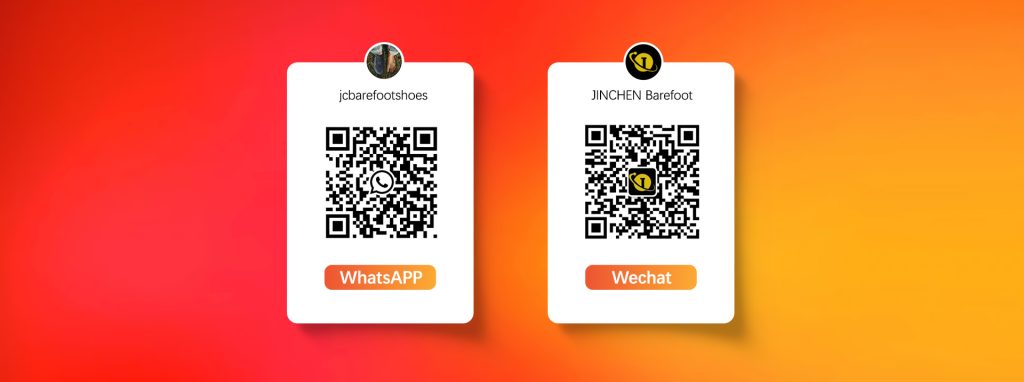

Ready to elevate your barefoot shoe brand with premium sole molds? Contact us today to discuss your customization needs and experience the difference of working with a trusted Chinese barefoot shoe factory!