As an environmentally friendly synthetic material, water-based suede leather has unique advantages in footwear manufacturing, and is particularly suitable for footwear designs that pursue comfort, fashion and sustainability.

I. Material properties and process innovation

Water-based suede leather is based on water-based polyurethane (PU) resin, and forms a fine suede texture through processes such as impregnation and sanding. Its structure usually includes a base fabric layer, a suede leather layer and a resin layer. The resin layer is provided with air holes and a water-absorbing layer, which can effectively improve the air permeability and moisture-proof performance. For example, the all-water-based suede microfiber developed by Huafeng Microfiber uses foaming technology to make the material have both elasticity and simulated leather effects, while reducing carbon footprint through water-based processes. The hollow biopolymer technology mentioned in some patents further enhances the softness and breathability of suede leather, while reducing the amount of resin used and optimizing production costs.

II. Shoemaking application scenarios and cases

1. Sports shoes: Water-based suede leather is widely used in sports shoes due to its lightweight and breathable properties. For example, the multi-scenario sports shoes jointly developed by Anta and Huafeng Microfiber use 1.2MM water-based suede microfiber, which combines retro style and functionality and is suitable for dad shoes, casual shoes and other categories. Adidas’ COURTSET tennis shoes also use suede uppers with fabric linings to enhance sports comfort.

2. Fashion casual shoes: The suede texture gives the shoes a unique retro aesthetic, such as FILA’s retro casual shoes, which achieve personalized design through high-saturation suede microfiber materials5. Fear of God x adidas’s joint model “Los Angeles Hiker” uses washed suede and a convex outsole to meet the needs of outdoor hiking and urban wear.

3. Children’s shoes and sandals: The softness and environmental friendliness of water-based suede make it an ideal choice for children’s shoes. For example, some sandals combine suede with breathable mesh to achieve both comfort and safety.

III. Environmental advantages and certification

1. Sustainable production: Water-based suede leather adopts solvent-free process, avoiding the use of harmful substances such as DMF in traditional oil-based leather production, and complies with EU REACH regulations and domestic environmental protection standards48. For example, Shandong Shian Microfiber’s water-based microfiber suede leather has passed SGS certification, using environmentally friendly dyes and water-based PU throughout the process to reduce wastewater discharge.

2. Circular Economy: Some companies further improve environmental protection through recycled materials or degradable processes. For example, Huafeng Microfiber’s REGEN series uses all-water manufacturing to reduce carbon footprint from the source and promote circular economy.

IV. Performance and cost comparison

1. Performance characteristics:

o Breathability: The air permeability design of the resin layer cooperates with the water absorption layer to allow moisture to be discharged in the form of water vapor, preventing the suede from being damp and affecting the breathability.

o Durability: The microporous structure of the water-based PU resin gives the material good elasticity and wear resistance, and some products use special surface treatment agents to enhance surface fastness.

o Comfort: The suede texture fits the foot, and the design such as Ortholite® insole improves the wearing experience19.

2. Cost advantage: By optimizing the slurry formula (such as mixing anions with easy-gel PU), the resin usage of water-based suede leather can be reduced by 30%-50%, and the cost of 200kg slurry can be reduced by 1,000-2,000 yuan. The cost advantage is significant after large-scale production.

V. Market trends and consumer feedback

1. Growth potential: The 2024 Global Water-Based Suede Leather Market Report shows that footwear is one of the main application areas, and the market size is expected to maintain steady growth in the next few years, with environmental protection and fashion needs becoming the main driving force.

2. Consumer preferences: The demand for personalized and environmentally friendly products among young groups has increased. Water-based suede shoes have a significant sales growth rate on e-commerce platforms because they are both fashionable and functional. For example, Anta’s co-branded models are hot-selling on channels such as Douyin, and consumers report that their “suede texture is high-end and suitable for daily matching”.

3. Maintenance suggestions: Suede leather needs to be cleaned regularly and waterproof spray should be used to prevent stains from penetrating. Some brands (such as Jiuxi) recommend using special care agents to maintain the suede fluffiness.

VI. Industry standards and certifications

Water-based suede leather must comply with standards such as QB/T 1002-2015 “Leather Shoes”, including indicators such as peel strength, abrasion resistance, and folding fastness16. In terms of environmental certification, some products have passed OEKO-TEX Standard 100 or ECOCERT certification to ensure that the limit of harmful substances meets international requirements.

Summary

Water-based suede leather is becoming an important material for footwear manufacturing due to its environmental protection, comfort and diverse design possibilities. Its application cases in sports shoes, casual shoes and other fields are increasing, and performance and cost are continuously optimized through technological innovation. For brands, combining the environmental selling point of water-based suede leather with fashionable design can effectively meet the market demand for sustainable products; for consumers, choosing such shoes can not only enjoy a comfortable experience, but also contribute to environmental protection.

As an export enterprise focusing on barefoot shoes, we are well aware of the market’s dual pursuit of “natural comfort” and “sustainability” – the lightweight texture of water-based suede (weight only 200-300g/m²) perfectly fits the core design concept of barefoot shoes “zero burden walking”. Its delicate suede (pile density 8000 strands/cm²) and highly breathable structure (water vapor permeability ≥500g/m²/24h) can bring users a natural experience like barefoot touching the ground. Relying on the mature water-based microfiber process production line (supporting OEKO-TEX® certification customization), we control the entire process from material research and development to finished product manufacturing, and can provide a one-stop solution for wear-resistant upgrades (20,000 wear tests), color customization (Pantone full color coverage) and environmental certification (REACH compliance) according to brand needs.

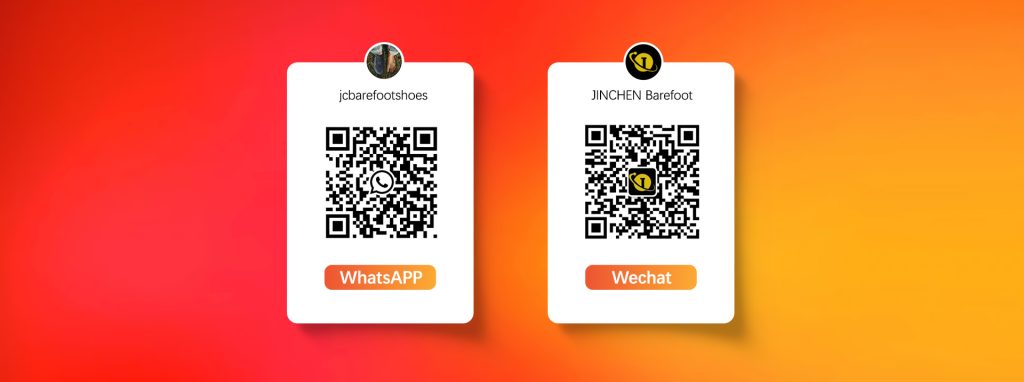

Dear partners, are you looking for high-quality materials and production partners that can meet consumers’ pursuit of “barefoot comfort” and convey the brand’s environmental protection proposition? Welcome to contact us for samples and customized production solutions of water-based suede barefoot shoes – let every step you take become a perfect resonance of nature and sustainability.